BX-2 (Tubing Dispensing Controller)

Main functions and benefits

The BX-2 Tubing Dispenser is a volumetric dispenser designed for precise fluid dispensing without the use of air pressure. Instead, it utilizes a rotating pump head to push fluid through the tubing, ensuring accurate material delivery with minimal waste. The dispenser is ideal for low-viscosity and anaerobic fluid materials, providing reliable dispensing for applications such as instant adhesives, inks, and similar products.

Key Features

- Volumetric Dispensing: Dispenses precise amounts of fluid through a rotating pump head, ensuring accuracy without the need for air pressure.

- No Pulsation: Delivers smooth and consistent dispensing, with no pulsation or tube wear during discharge.

- Low-Viscosity Fluid Compatibility: Suitable for applications involving low-viscosity and anaerobic fluids, such as adhesives and inks.

- Liquid Suction and Control: Equipped with a liquid suction function, forward/reverse rotation, and an automatic timer function for convenient control over the dispensing process.

- Direct Fluid Dispensing: Fluids are sucked directly from the container, eliminating the need for additional containers or compressor air, reducing complexity and cost.

- Adjustable Dispense Amount: Dispense volume can be manually or automatically adjusted via the integrated timer, making it versatile for various applications.

Product specifications

| Model | BX-2 |

| Control Method | Electronic / Pneumatic System |

| Dispensing pressure | 0.15kg/cm2 |

| Time Range | 0.01~99.99 sec |

| Rotor Speed | 0~120rpm(max.) |

| Flow Speed | 0.01~6ml/min.(Teflon Tube) 0.1~20ml/min.(Silicone Tube) |

| Material Viscosity | 300cps(max.) |

| Pump Direction | Both Direction(Forward & Reverse) |

| Power source | AC100~220V 50/60Hz(Free voltage) |

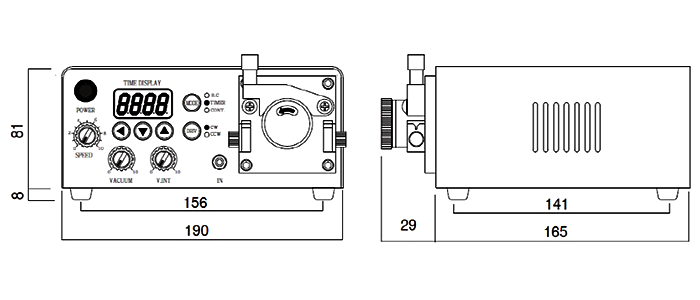

| External Dimension & weight | 190(W) x 165(D) x 81(H)mm, 2.6kg |